2025.09.25

Product Highlights

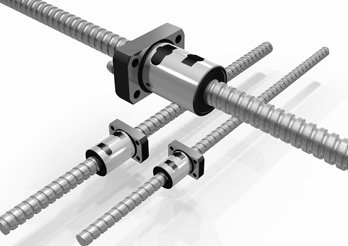

How Kuroda Precision Redefines Precision with Advanced Ball Screw Technology

Precise components are crucial to optimizing performance when your system depends on accurate movement. In the semiconductor, medical, machine tool, robotics, and many other types of equipment, even minor deviations can cause significant problems. Kuroda Precision produces a wide variety of ball screws designed to reduce motion error, minimize torque variation, and maintain tight tolerances. Kuroda ball screws are built to deliver reliable, repeatable performance where precision matters most.

Kuroda JenaTec has more than a century of experience in precision steel processing and measurement. In 1925, we started with precision gauges and now produce advanced ball screws using the same high standards. We build our own grinding machines, giving us control over quality from start to finish.

Our production facilities are also carefully managed. We maintain a constant temperature of 23°C ±1° with humidity below 60%. The factory foundations are designed to prevent vibration during production. Every ball screw undergoes outgoing inspection for smooth motion and strict adherence to product specifications. Our plants in Japan and Germany are ISO 9001 and 14001 certified.

Kuroda doesn’t believe in one-size-fits-all ball screws. We offer a wide range of product series, each designed for a specific type of motion requirement. Whether you need low noise, compact form, or high-speed operation, precision is built into the core of each model.

Each of our ball screw designs addresses precision from a different angle. For example:

Popular Series Include:

A Series (SIDE DEFLECTOR™ Method)

High-speed, compact, and built-for-demanding motion systems

G Series (Tube Method)

Ideal for transport and positioning tasks, available in many sizes

F Series (End Deflector Method)

Low noise, perfect for labs and sensitive environments

D Series (Deflector Method)

Designed for precision in compact spaces

HG Series (End Cap Method)

Multi-start threads and long leads for high-speed machines

GW/GY Series

Rolled ball screws for standard automation and conveyance

R Series

Resin nuts for low cost, lighter loads, and reduced maintenance

PW/PY Series

Lead screws with resin nuts, designed for low cost and smooth motion

Application Precision in Practice

You will find our ball screws in various semiconductor related applications, medical applications such as surgical robots and dispensing devices, machine tools, robotics, aerospace and many more, but what matters more is how they perform there. In CNC machining, for example, stable torque and minimal backlash result in smoother surface finishes, especially in reverse-direction cuts. In aerospace, tighter tolerances reduce mechanical drift, critical control surfaces, and actuated components. Robotics demands consistent motion over many cycles; our screws hold accuracy longer, reducing recalibration and downtime.

We stock 80 to 85 percent of standard linear rail and ball screw components at our Kennesaw, Georgia facility. Local machining also helps avoid delays from overseas shipping. Standard items ship quickly, and in urgent cases, we can machine custom ball screws in as little as one week.

When speed matters, we also offer expedited air freight. Thanks to our responsive support and local inventory, we’ve helped companies deliver full orders in under two weeks.

Kuroda JenaTec combines global manufacturing strength with local service and technical support. Our ball screws are tested, proven, and trusted by engineers across industries. Visit our technical information page or contact us directly for a quote or application support.