2025.08.08

Topics

What Is a Linear Motion Guide and How Does It Improve System Accuracy?

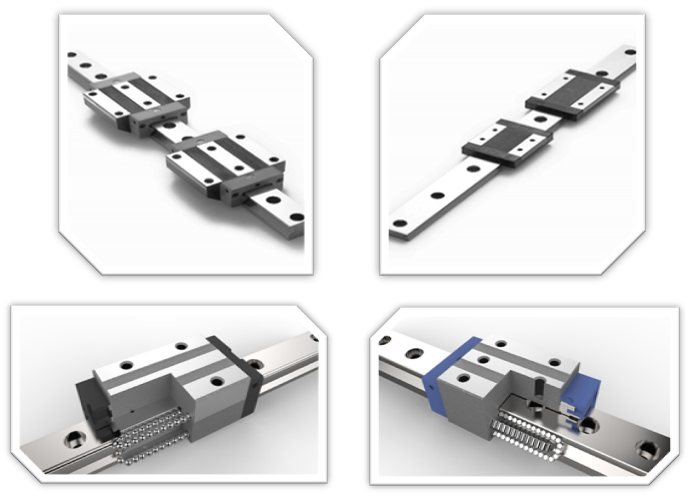

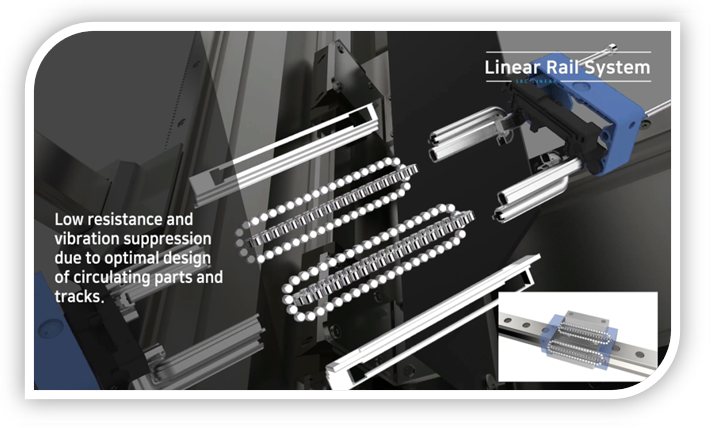

A linear motion guide is a mechanical component that allows for precise, low-friction movement along a straight path. These components, also known as linear guideways, support controlled, repeatable travel in semiconductor systems, medical analyzers, automation equipment, CNC machinery, and many others.

By replacing traditional sliding with rolling contact, linear motion guides improve speed, reduce wear, and maintain positional accuracy. For engineers building high-performance motion systems, they are a fundamental part of reliable machine design.

Why Linear Motion Guides Matter in Precision Systems

Precise, repeatable movement ensures productivity and product quality. Here’s where linear motion guides make a difference:

- CNC Machines: Maintain exact cutting paths for fine-tolerance work

- Robotics: Guide arms, lifts, and gantries with smooth, low-drift movement

- Semiconductor Tools: Enable sub-micron placement and rapid indexing

- Medical Devices: Deliver quiet, smooth actuation in imaging and diagnostic equipment

Linear motion guides help reduce backlash, maintain alignment, and support high acceleration and deceleration. Each feature makes linear motion guides essential for consistent performance in fast-moving, high-precision applications.

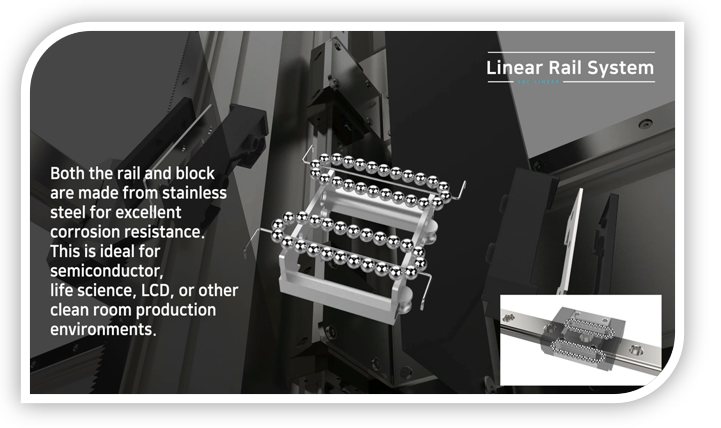

Built for Demanding Applications

- Semiconductor and electronics assembly

- Automated production systems

- Aerospace and medical devices

- Robotics and high-speed automation

These environments require motion systems that are compact, quiet, clean, and accurate. We offer various sizes and styles, matching your load, speed, and mounting requirements.

Many of our guides are compatible with cleanroom environments and can be integrated with custom slide units or actuators to save engineering time.

Several factors go into selecting the right linear guide for your application:

- Load capacity and orientation (vertical, horizontal, or inverted)

- Travel distance and required stroke

- Speed and acceleration limits

- Precision class and allowable runout

- Environmental exposure (dust, fluids, cleanroom, etc.)

Kuroda jenatec supports multiple guide options with different load ratings, preloads, and seal configurations. Our engineering team can help identify or customize a suitable solution if your application requires a unique solution.

Kuroda jenatec maintains inventory and machining capabilities at our Kennesaw, Georgia, facility to support U.S. customers. Standard components ship quickly, and our local team can support shortened lead times for modified assemblies or customized mounting. This helps reduce your time to market without compromising product quality.

Whether you're sourcing new equipment or replacing worn guideways, we offer consistent quality backed by global manufacturing and local service.