What is ball screw thrust? (2)

In the previous article, it was explained that Ball Screws "can be moved more smoothly with the same force". This article is a simplified explanation of the reason of such feature.

First, when an object can be moved more smoothly with the same force, it indicates high mechanical efficiency; that is, mechanical efficiency and thrust are closely related. This is due to a feature of the Ball Screws.

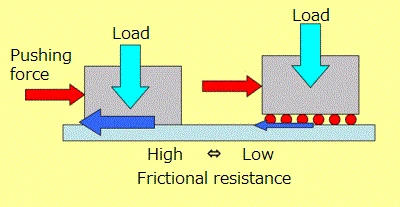

A trapezoidal screw and a triangular screw are a type of slide screw consisting of a screw shaft and nut. When the screw shaft is rotated, the external thread and internal thread of the shaft and nut, which have some contact, move by rubbing against each other. (Left side of Figure 1)

In a ball screw, the screw shaft and nut are both internal threads. When the screw shaft is rotated, it can move more smoothly converting more energy into thrust because the rolling balls in between the two internal threads act as a guide. (Right side of Figure 1)

In the case of a ball screw, the mechanical efficiency is over 90%, so when the screw shaft is rotated with an input energy of 100, 90% of it is converted into thrust (≒ work).

On the other hand, a sliding screw has a mechanical efficiency of 30%, so for every 100 input energy, 30% is converted into thrust (≒ work). To use an automobile analogy, if the mechanical efficiency of the parts used is high, a greater proportion of the engine's output can be converted into driving force, improving fuel efficiency. The use of balls or cylinders between two objects to reduce frictional resistance has been known for a long time, and was even used to transport stone for the pyramids.

"Knowing the past" may be an exaggeration, but it is very interesting that the same principles have been used from ancient times to the present day.

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.