What is the fit of ball screw mounting parts?

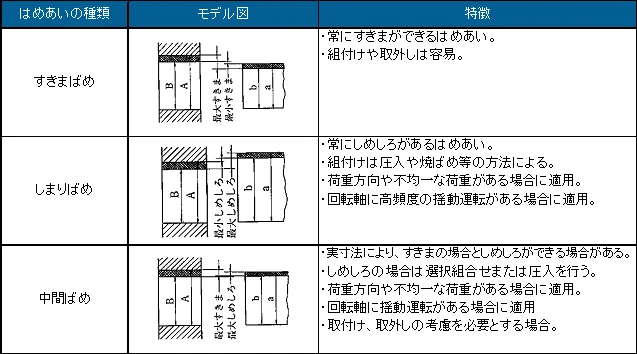

Generally, when using a ball screw, both ends of the ball screw shaft must be supported by bearings. The shaft and bearing are assembled using a "fit," which is the relationship of clearance resulting from the difference in dimensions between the hole and shaft. There are three types of fits: "loose fit," "tight fit," and "transition fit," which indicate the degree of firmness (the opposite is looseness) when assembling the shaft and bearing parts. The use of each type must be selected according to the operating conditions and load conditions of the machine, and the characteristics of each are shown below.

Types and features of fits

For ball screw fits, in addition to ensuring ball screw accuracy for positioning without vibration, it is also necessary to consider installation and removal for maintenance to maintain accuracy. In that sense, the fit tolerances recommended for general rolling bearings are inconvenient for the bearing mounting part, so it is reasonable to use an "intermediate fit" or a "clearance fit" that is set so that the amount of clearance is as small as possible for the fit between the bearing inner ring and the outer diameter of the bearing mounting part. The fit tolerances for general bearing mounting parts are shown below.

Bearing mounting part fit tolerance

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.