How do you inspect Ball Screws?

Ball Screws undergo intermediate inspections during the manufacturing process and final inspections after the product is completed to determine whether it is good or bad. In these cases, the pass/fail judgment is based on the JIS standard, the dimensions and tolerances specified on the drawing, and the standards set forth in KURODA's inspection standards.

The main inspection items are divided into four categories:

1. Inspection items

Length of the terminal and screw shaft, outer diameter of the terminal, pass/fail judgment of the triangular thread processing part and keyway processing part, nut length, outer diameter of the body, appearance of the nut flange part, mounting part dimensions, etc. are based on instructions on the drawing.

2. Exterior dimensions

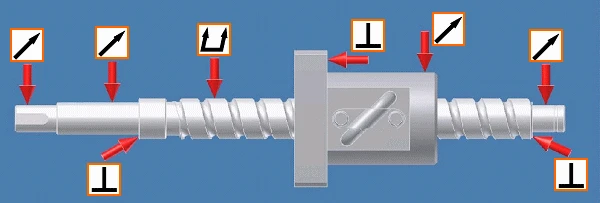

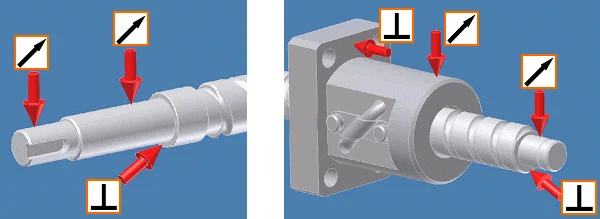

Radial runout of parts and bearing mounting parts, squareness of mounting parts such as bearings, radial runout of the outer circumferential surface of the nut, squareness of the nut flange mounting surface, total runout of the screw shaft center (degree of curvature of the entire screw shaft), etc. according to instructions on the drawing.

Please see the diagram below for measurement positions and symbols.

3. Lead accuracy

Cumulative representative lead error, various tolerances for variation in effective length of thread, etc. - according to drawing instructions

4. Operation

Axial clearance, preload condition, operability (does it move smoothly?) etc. - according to the drawing instructions

The precision of the mounting parts of each part is standardized for posture and runout by geometric tolerances, and the allowable values are determined for each precision class.

For general Ball Screws, the geometric tolerances shown in the figure below are specified.

- Please refer to our catalog for the measurement standards for each geometric tolerance.

Technical information list about Ball Screws

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.