Why are there length limitations on Ball Screws?

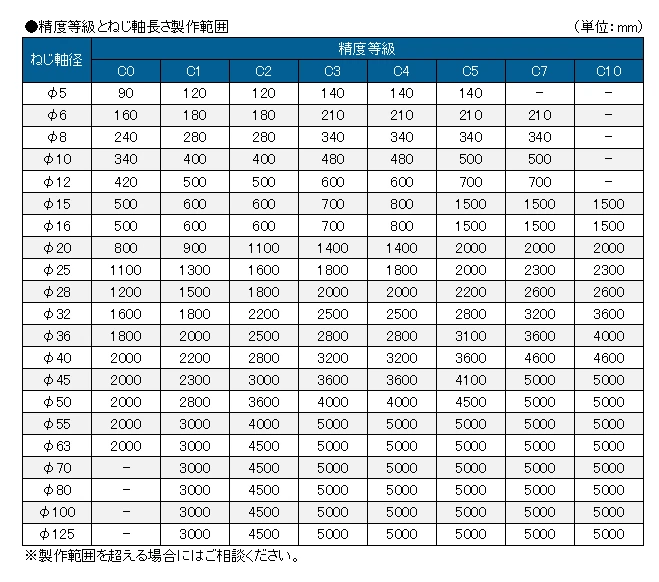

There are no specific restrictions on the length of Ball Screws in the JIS standard. This is because the JIS standard determines the accuracy within the range that can be manufactured using standard processing methods, and lengths outside of this range are often managed by the manufacturer's own standards.

Factors that limit the manufacturing length of the shaft are:

- The shaft has a large slenderness ratio (shaft length/shaft diameter)

The longer and thinner the screw shaft (the larger the ratio of shaft length to shaft diameter), the more difficult it is to manufacture, so generally, the smaller the shaft diameter, the shorter the limit on the manufacturing length.

- High-precision shafts

The higher the precision grade of the shaft, the stricter the allowable runout precision of the shaft, making it more difficult to manufacture a long shaft (because the tolerance for each precision grade must be satisfied over the entire shaft length).

Furthermore, a long and slender shaft has a low (small) allowable rotation speed (shaft critical speed = shaft natural frequency) and a low buckling load against an axial load, and is therefore often not suitable for use with Ball Screws, so there is no need to manufacture an unnecessarily long shaft.

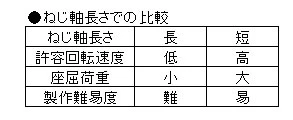

When comparing two Ball Screws with the same shaft diameter, the following can generally be said:

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.