How are Ball Screws used?

A ball screw is a mechanical element that converts the rotary motion of a motor, etc. into linear motion. Its main applications include transportation and positioning in semiconductor manufacturing equipment, industrial robots, and machine tools.

For example, in machine tools that operate under numerical control, known as NC machines, Ball Screws are used to form the feed mechanism and achieve precise positioning accuracy. Or, in amusement machines such as UFO catchers found in game arcades, Ball Screws are used to move the arms that grab prizes back and forth (transport) side to side.

Currently, Ball Screws are used in a variety of machines (food equipment, medical equipment, printing equipment, amusement equipment), as well as in vehicles such as automobiles, trains, and aircraft.

Basic uses of Ball Screws include the transportation and positioning of heavy objects (workpieces).

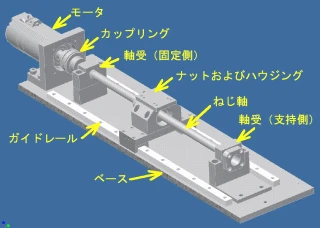

The important thing to remember here is that a ball screw is a "machine element that receives loads only in the axial direction and converts rotational motion into linear motion." Since the ball screw moves the table linearly in the axial direction, the axial load is applied to the screw shaft via the nut. The structure must be such that the guide rail bears other loads (vertical loads, moment loads, etc.).

Therefore, a linear motion mechanism that includes a general ball screw is composed of a ball screw + guide rail + power source (motor). This is the same for precision machine tools and amusement equipment such as UFO catchers.

In actual machinery, Ball Screws tend to be hidden by exterior covers or tables, but when you look at machinery performing linear motion, remember the ball screw structure and try "ball screw watching."

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.