What is the circulation system of a ball screw?

A ball screw has steel balls placed between the screw shaft and the nut, and the steel balls circulate while rolling. After rolling around the outer periphery of the screw groove a specific number of times, the steel balls are guided by a circulation part and return to their original position. The circulation of the steel balls in this way is called forming a "circuit," and Kuroda Precision Industries currently has five types of circulation methods as standard. Here we will explain the characteristics of the different circulation methods.

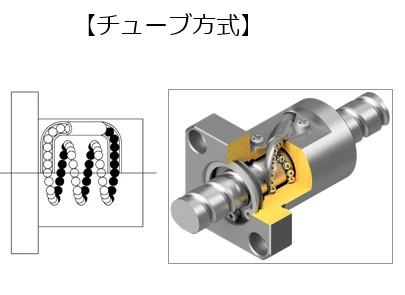

①Tube method

-

This is the most common circulation method, and uses a tube bent into a U-shape as the circulation part. In this method, the steel balls guided by the tube roll around the outer circumference of the screw groove 1.5, 2.5, or 3.5 times (depending on the product specifications) before being guided back into the tube to form one circuit. It is possible to incorporate multiple rows (circuits) for one nut to increase the rated load, and it is highly customizable and can be used for a wide range of Ball Screws, from small to large leads.

-

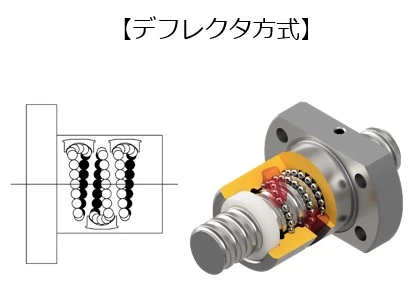

②Deflector method

-

This is the most compact circulation method with excellent rotational balance. The steel balls that roll between the screw shaft and the nut are guided by a deflector inserted inside the nut, and form a circuit by going over the outer diameter of the screw shaft and returning to their original position. As with tubes, multiple rows can be incorporated into one nut, and the range of rated loads that can be secured is wide, making this a circulation method suitable for small leads.

-

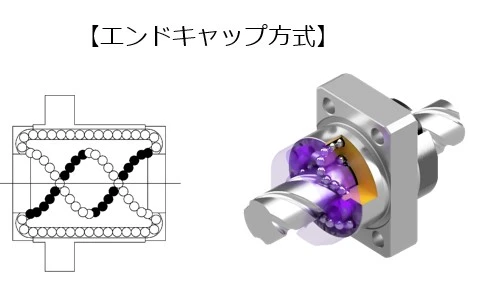

③End cap method

-

This is a circulation method in which the end caps attached to both ends of the nut have the function of scooping up and returning steel balls. The nut body has through holes to allow the steel balls to pass back and forth. This method is used for large lead Ball Screws. In addition, this method allows the screw shaft to have a large number of threads, making the nut shape more compact and ensuring the rated load.

-

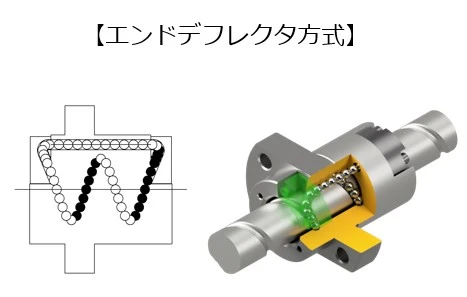

④End deflector method

-

This is a circulation system in which the end deflectors attached to both ends of the nut have the function of scooping up and returning steel balls. Through holes are provided in the nut body to allow the steel balls to move back and forth. The explanation so far is the same as for the end caps, but the differences include high peripheral speed and quietness. Designed to pursue a smooth flow of steel balls, the steel balls circulate with natural movement, achieving improved performance while maintaining a compact size. The applicable lead range is wide, from medium lead to large lead Ball Screws.

-

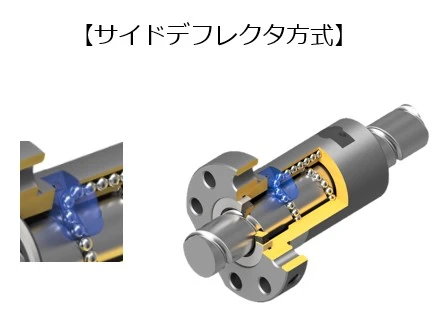

⑤Side Deflector System (SIDE DEFLECTOR™)

-

This is a circulation method in which steel balls are scooped up by the side deflector embedded inside the nut, and then returned to their original position through a through hole provided in the nut body for the steel balls to move back and forth. Like the end deflector, it is designed to pursue a smooth flow of steel balls, so the steel balls circulate with a natural movement, and it combines high peripheral speed, quietness, and compactness. This circulation method is available in the AD and AH series that comply with DIN standards, and this series also supports the lubrication unit LUBSEAL™ as standard.

-

- Small lead: The lead is smaller than the nominal diameter of the screw shaft, etc.

- Medium lead: The lead is 1x, 1.5x, etc. the nominal diameter of the screw shaft.

- Large lead: The lead is 2 or 3 times the nominal diameter of the screw shaft.

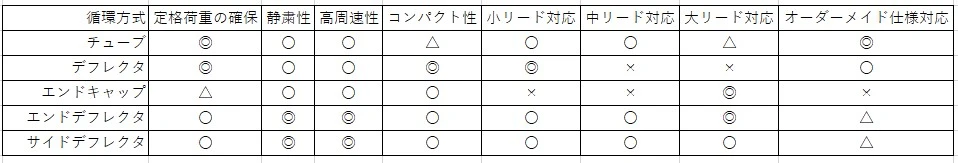

The above five types are the circulation methods currently supported as standard by Kuroda Precision Industries, and the characteristics of each type are summarized in the table below. Please use this as a guide when selecting your system.

The designs from the top down, from the tube type to the side deflector type, were created in the older era, so the designs of the circulation parts become more sophisticated as you go down. However, as shown in the table, when considering the characteristics of each method (rated load, quietness, high peripheral speed, compactness, lead, need for custom-made, etc.) and the required specifications, there is no circulation method that is superior in all respects, so you need to select a method that takes into account the balance between these.

This is an explanation of the characteristics of the different circulation methods. Kuroda Precision Industries is always working on research and development of products that meet the needs of the times, and will propose Ball Screws that are best suited to the customer's required specifications based on our extensive track record. Please contact your nearest sales office if you have any inquiries.

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.