What are the materials and heat treatment of a ball screw?

A ball screw is a machine element that consists of a screw shaft, a nut, steel balls, and parts that circulate the steel balls. Each component is generally made of metal, with the appropriate material being used for each part.

Due to the characteristics of the ball screw, the hardness of the screw groove surface of the screw shaft and nut has a significant effect on the lifespan. In addition, the strength of each part must satisfy the requirements as a transmission element.

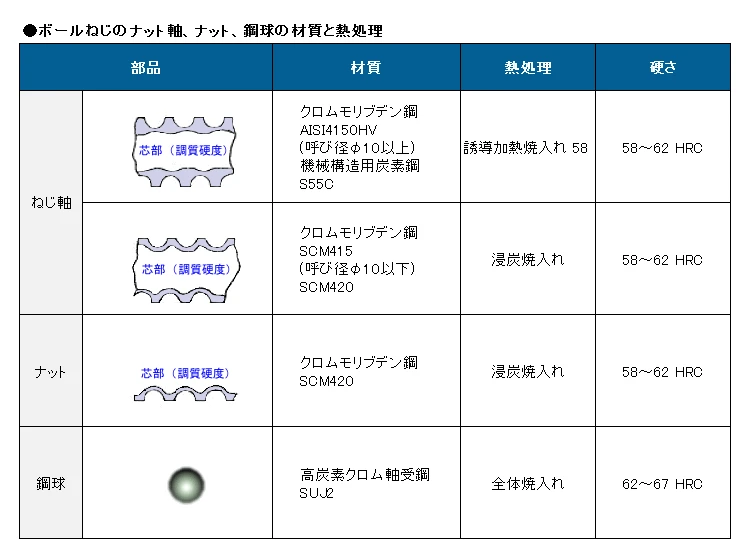

The materials and heat treatment of the screw shaft, nut, and steel balls of a ball screw are shown in the table below.

The parts that circulate the steel balls differ depending on the circulation method, but are mainly made of stainless steel or carbon steel for machine construction.

The screw groove surface of both the screw shaft and nut of the ball screw is surface hardened for the following reasons:

- The hardness of the thread groove surfaces of the screw shaft and the nut has a significant effect on their service life, so the surfaces are hardened.

- If the core is hardened, it will lose its toughness and become hard and prone to snapping, so the core must be kept soft.

For special environments such as in a vacuum, clean room, or chemical resistance, stainless steel (SUS440C) is used for the screw shaft, nut, and steel balls. Of course, heat treatment is performed to harden the screw shaft and nut thread groove to 56-59HRC, and the steel balls to 59HRC or higher.

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.