What is the purpose of lubrication for a ball screw?

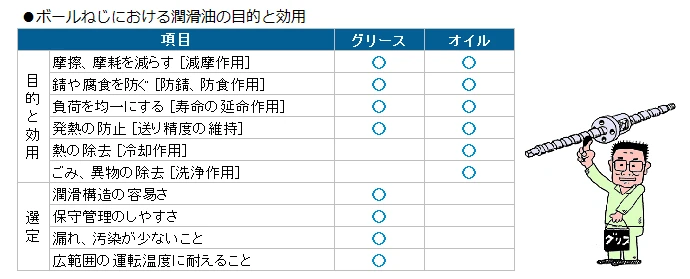

Lubrication is “reducing friction between surfaces that come into contact with each other, such as machines.” The role of lubricants in Ball Screws is to reduce friction and wear, and to maintain the excellent characteristics and functions of Ball Screws over the long term, by providing rust prevention, cooling, and cleaning effects. Lubricants can be broadly divided into two types: grease and oil, and the type must be selected according to the conditions and purpose of use. In the case of Ball Screws, grease is generally used, which is easy to maintain and economical, and oil, which requires frequent lubrication, is rarely used except for machine tools equipped with centralized lubrication systems and special machines and devices that require cleaning and cooling effects.

Unless otherwise specified, KURODA ships the product with Albania Grease S2 sealed in the nut as a lubricant. For lubricants suitable for Ball Screws, we recommend lithium soap-based grease with excellent water and heat resistance, and spindle or turbine oil #90 to #180.

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.