Why is preload necessary?

One of the features of Ball Screws is their low backlash. To eliminate backlash, the axial clearance is made small, which requires preload.

Precise positioning can be achieved by setting the appropriate amount of preload. However, applying too much preload can cause temperature rise and shorten the lifespan, so it is important to set the appropriate amount of preload.

There are the following methods for applying preload. At KURODA, we use overball preload for light and medium loads, and the double nut preload pin method as standard for medium loads and above.

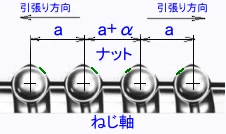

Overball preload

-

This method applies preload with one nut. A steel ball that is slightly larger than the ball groove space is inserted, and the balls come into contact at four points to apply preload. Suitable for light and normal preload.

-

Integral preload

-

This is a method of applying preload with one nut. The preload is applied at the center position of the nut (between the circulation parts) by shifting the lead by an amount equivalent to the preload load. This is suitable for normal preload.

-

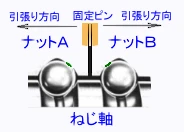

Double nut preload (pin method)

-

This method uses two nuts and applies a specified preload by rotating them to tighten them together. A fixing pin is inserted into the nut to prevent rotation. Suitable for medium to heavy preload.

-

Double nut preload (spacer method)

-

This method uses two nuts with a spacer between them to apply a specified preload. Suitable for medium to heavy preload.

-

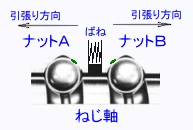

Spring preload

-

This method uses two nuts and a spring between them to provide a specified preload. It is suitable for situations where you want to keep torque fluctuations as small as possible.

-

Technical information list about Ball Screws

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.