What options are available for ball screw actuators?

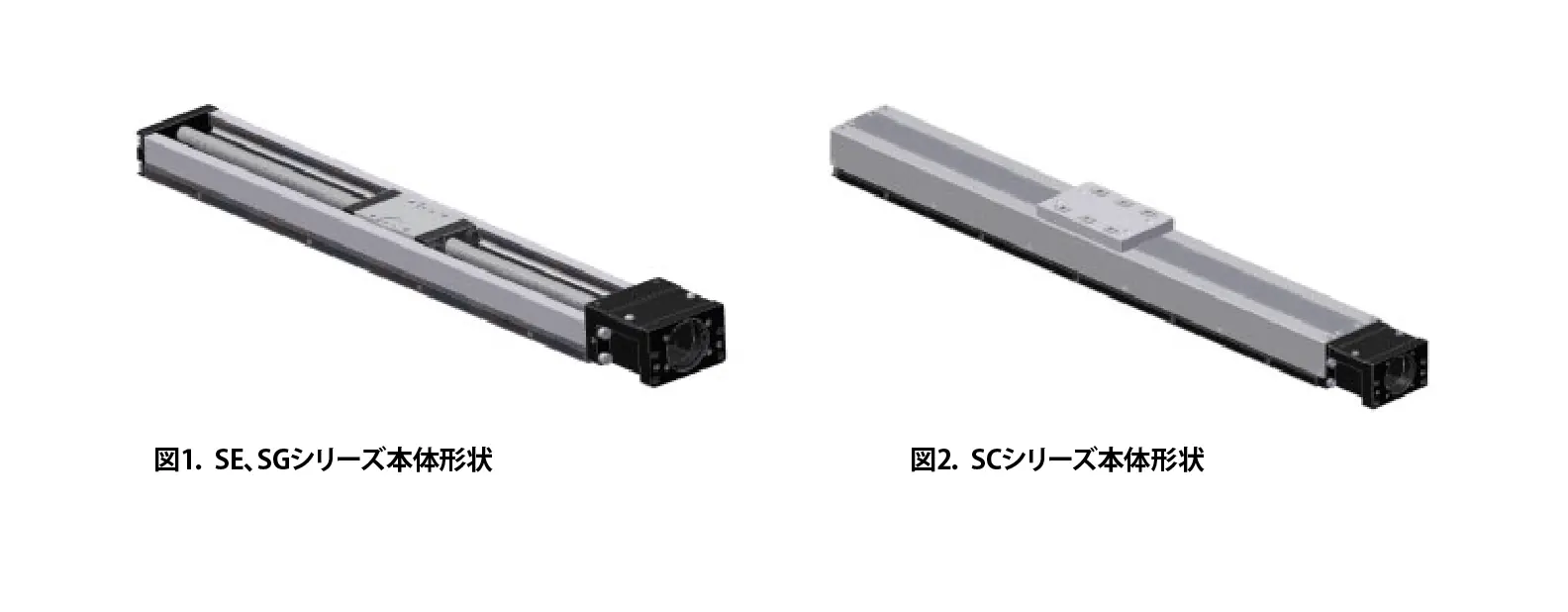

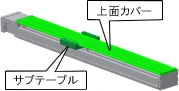

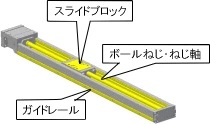

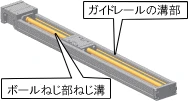

First, the body shape of a ball screw actuator is as shown in Figure 1 or Figure 2.

Options include the addition of parts that can be installed or removed without disassembling the main body, surface treatment of steel parts for rust prevention, grease specifications for clean environment compatibility, etc.

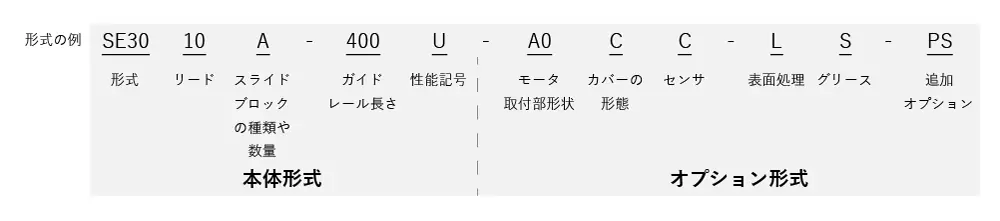

The Model numbers are displayed as option numbers following the main body number as shown below.

See below for an overview of each option.

Motor mounting shape

Motor bracket

Target series

- SG Series

- SE Series

- SC Series

Typical shape

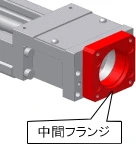

Intermediate Flange

Target series

- SG Series

- SE Series

- SC Series

Typical shape

- The intermediate flange is used by attaching it to the motor bracket for direct motor connection.

- The procedure for installing the intermediate flange may vary depending on the motor type you are using.

Please contact us for more details.

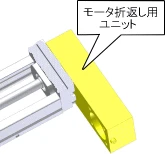

Motor folding unit

Target series

- SG Series

- SE Series

- SC Series

Typical shape

- The motor bracket uses a housing type with a spigot.

- The folding direction can be up, down, left or right, allowing you to select the direction that best suits your specifications.

Please contact us for more details.

Cover Type

Top cover

Target series

- SG Series

- SE Series

Typical shape

- The top cover is included in the set, along with a sub-table.

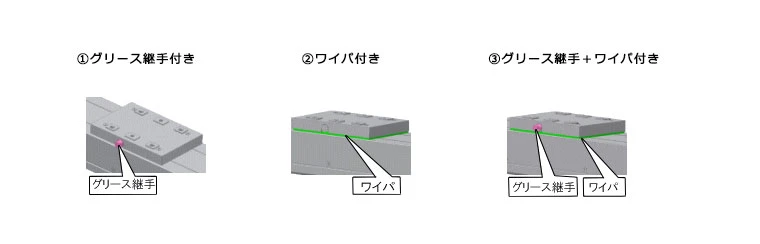

① With grease fitting ② With wiper ③ With grease fitting + wiper

Target series and representative shapes

- SC Series

Sensors

Photomicrosensor / Proximity sensor

Target series and representative shapes

- SG Series

- SE Series

- SC Series

Surface Treatment

Anti-rust black coating

Target series

- SG Series

- SE Series

- SC Series

Typical shape

- Anti-rust black coating is applied to the steel parts of the ball screw, slide block, and guide rail. (Yellow parts in the model diagram on the left)

Grease

Low dust generation grease

Target series

- SG Series

- SE Series

- SC Series

Typical shape

- The low dust emission grease is applied and sealed into the ball screw groove and the guide rail groove (orange part in the model diagram on the left).

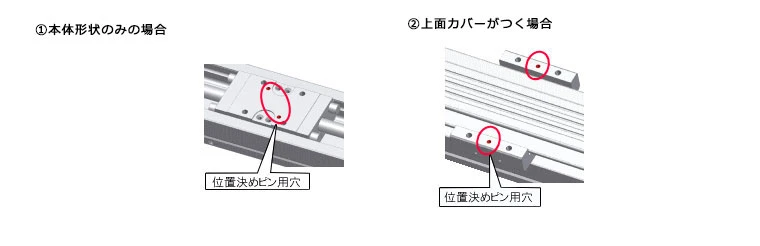

Positioning pin hole

① Main unit only ② Top cover included

Target series and representative shapes

- SG Series

- SE Series

Please note that guide rail length, motor mounting shape, sensor specifications, grease specifications, motor assembly, etc. that are not listed in the catalog are not treated as options.

Please contact us for details.

Technical information list about Ballscrew Actuators

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.