What should I pay attention to when using a ball screw actuator?

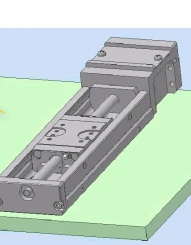

As explained above in "What is a ball screw actuator?", the guide section, ball screw section, and bearing section of a ball screw actuator are centered and made into a unit, so it can be operated by installing a motor as a drive source.

However, although it is sufficient for the product to simply function, it is a precision instrument and various performance and accuracy must be ensured. Therefore, the following precautions must be observed during design and use to use the product safely and correctly and to prevent personal injury or damage.

Design considerations

1. Pay attention to the shape and precision of the location where the actuator is installed.

2. Use within the allowable specification ranges, including allowable speed, rated load, stroke length, and operating temperature.

3. Pay attention to strong impacts and excessive moments.

4. Pay attention to foreign matter adhering to or getting mixed in.

5. Pay attention to the behavior of the table during emergency stops.

(If installed in a vertical or inclined location, the table may fall under its own weight.)

6. Cannot be used underwater or in wet environments.

7. Cannot be used for military-related applications such as weapons or arms-related applications.

Precautions for use and assembly

1. Pay attention to centering and alignment when assembling.

2. Take care not to damage the guide rail, the mounting surface of the table, or the exterior cover parts.

3. Make sure that the fixed and connected parts of the actuator are securely fastened so that they do not come loose.

4. Take care not to allow dirt or foreign matter to adhere to or get mixed in.

5. Do not start the device until you have confirmed that it is operating properly.

6. Never touch the area near the stroke end of the table movement part or the rotating part of the ball screw shaft while it is operating, as there is a risk of your fingers being pinched or entangled.

7. Never disassemble the ball screw actuator.

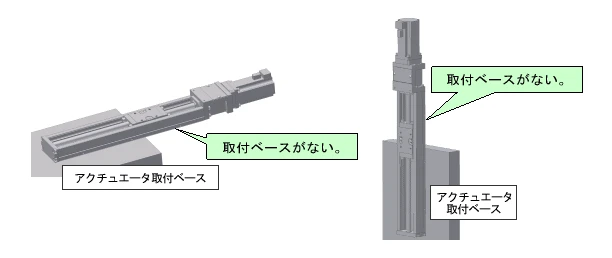

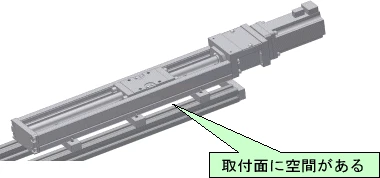

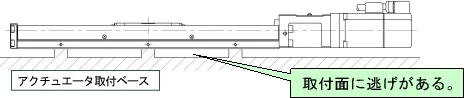

(Example) Inappropriate installation example when installing an actuator

Of the various points to be aware of, this time we will explain the importance of paying attention to the shape and precision of the location where the actuator is installed.

Ball screw actuators are designed to demonstrate their performance and precision by installing the bottom of the guide rail on a base.

Therefore, the guide rail mounting surface and the base side material that comes into contact with it must be made of a material with sufficient rigidity, have a flat mounting surface, and have mounting space that covers the entire mounting surface.

If the mounting shape does not have enough flatness or mounting space (see the diagram below), the guide rail may deform, impairing not only performance and precision but also operability, causing noise, early wear, and shortened life.

I: There is no mounting base on the entire surface of the guide rail mounting surface.

II: There is a gap or clearance between the guide rail mounting surface and the mounting base, and the entire mounting surface is not supported.

III: The flatness of the surface on which the guide rail is attached is poor.

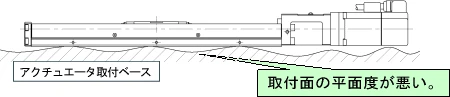

Recommended Installation

-

- Install the actuator so that the entire mounting surface of the mounting base is in contact with that of the mounting base.

- Be sure to use all the bolts to secure the guide rail.

- Please contact us regarding the flatness of the mounting base.

-

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.