How do I select a ball screw actuator?

In this first part about the selection method, we will explain the general flow of the selection procedure.

Just like selecting a ball screw, there is no single procedure for selecting a ball screw actuator.

Here, we will show you a simple but general procedure for selecting a ball screw.

How to select a ball screw

[Consider operating conditions] → [Consider lead, screw shaft diameter, and overall screw shaft length]← → [Consider nut shape, number of cycles, etc.]← → [Calculate lifespan] → [Consider accuracy] → [Consider lubrication, dust protection, etc.] → [Decide type]

- The locations marked with the arrows "← →" require a reconsideration of the operating conditions depending on the results of the life calculation.

How to Select a Ball Screw Actuator

For ball screw actuators, the combination of screw shaft diameter and lead, number of nut rotations, screw shaft length, guide rail length, positioning accuracy, etc. are fixed for each size, so a provisional size is selected based on the operating conditions, and the lifespan of each element, the guide, ball screw, and bearing, is calculated.

The provisional selection is performed under the initial operating conditions, which is where it differs from the selection of a ball screw. The selection procedure for a ball screw actuator is shown below.

1. Consideration of usage conditions

●Work table weight

In addition to the workpiece mass, the table mass is also included.

●Feed speed

In addition to the maximum value, please also provide the commonly used value.

●Stroke

Please provide the maximum and minimum values.

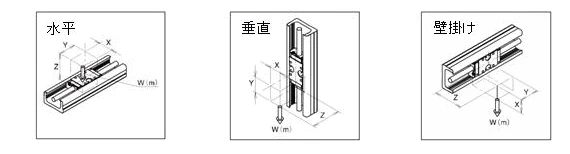

●Installation status

Horizontal, vertical and wall-mounted installations are available.

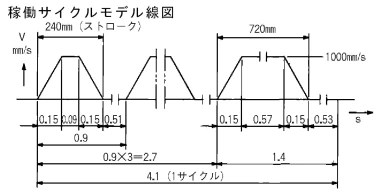

●Operation cycle

Please prepare the operating conditions for one cycle. A model diagram like the one below is useful.

●Desired lifespan

Excessive settings may result in oversizing, so be careful!

●Positioning accuracy and other precision

Please refer to the catalog for standard values such as repeatable positioning, absolute positioning, and running parallelism.

●Usage environment

Temperature of the operating environment, type and amount of dirt and foreign matter, use in a clean room, etc.

2. Provisional selection of format

●Limit stroke

The stroke limit varies depending on the type and number of slide blocks. Please be careful!

●Allowable speed

The allowable speed will change depending on the lead and guide rail length you select. Please be careful!

●Positioning accuracy and other precision

Indicates the precision of positioning (high precision, simple positioning, etc.)

3. Calculating the lifespan of each element

●Guide life calculation

In the guide section, it is necessary to consider moment loads as well as radial loads.

●Ball screw life calculation

The ball screw section can only support axial loads.

●Bearing life calculation

The bearing section can only support axial loads.

4. Lubrication, dust prevention, etc.

●Grease used

Please select the grease that is appropriate for the environment in which you will be using it. Clean environment grease is also available.

●Presence or absence of covers

We also offer types with top covers and full covers.

●Motor mounting part shape

The shape of the motor mounting part varies depending on the motor used. It is compatible with various motors.

●Surface treatment or not

It is effective in environments where anti-rust oil cannot be used, such as clean rooms.

●Consider the type of sensor

We offer photomicrosensors, proximity sensors, etc. Please see the catalog for details.

●Positioning pin hole

It is convenient when disassembling and assembling (including reassembly) machinery and equipment.

5. Decide on the format

●Check the format

Please check that there are no missing entries in the main body format and option format.

--------

- In steps 2 and 3, depending on the selection results, it may be necessary to change the specifications and conditions in step 1.

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.