What is the difference between conventional metric thread gauges and Unified Thread Gauges for inspection and machine work?

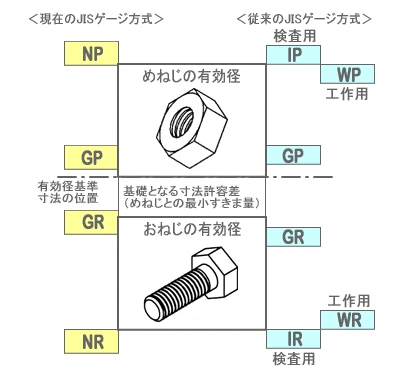

Conventional metric thread gauges and unified thread gauges have the same go-side thread gauge, but

there is a distinction between inspection and machining gauges on the no-go side.

Machining gauges have a gauge tolerance inside the thread tolerance limit, while inspection gauges have a gauge tolerance outside of that limit, so that something that passes the machining gauge will not fail the inspection gauge. It is common for the manufacturing side to use the machining gauge, and the receiving side to use the inspection gauge.

Current JIS

The current JIS was established based on ISO 1502 and does not distinguish between inspection and manufacturing.

Therefore, all current JIS gauges are for both inspection and manufacturing.

The dimension settings are close to those for conventional inspection.

[Effective diameter relationship diagram]

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.