Ultra-fine bubbles

Revolutionary high-efficiency machining

Grinding efficiency is dramatically improved using grinding fluid containing ultra-fine bubbles. This enhances cooling performance, reduces machining time, and improves dimensional accuracy.

MENU

We meet these needs and solve these challenges

- Reduction of processing time

- To improve machining surface accuracy, Concerned about variation in grinding surface quality

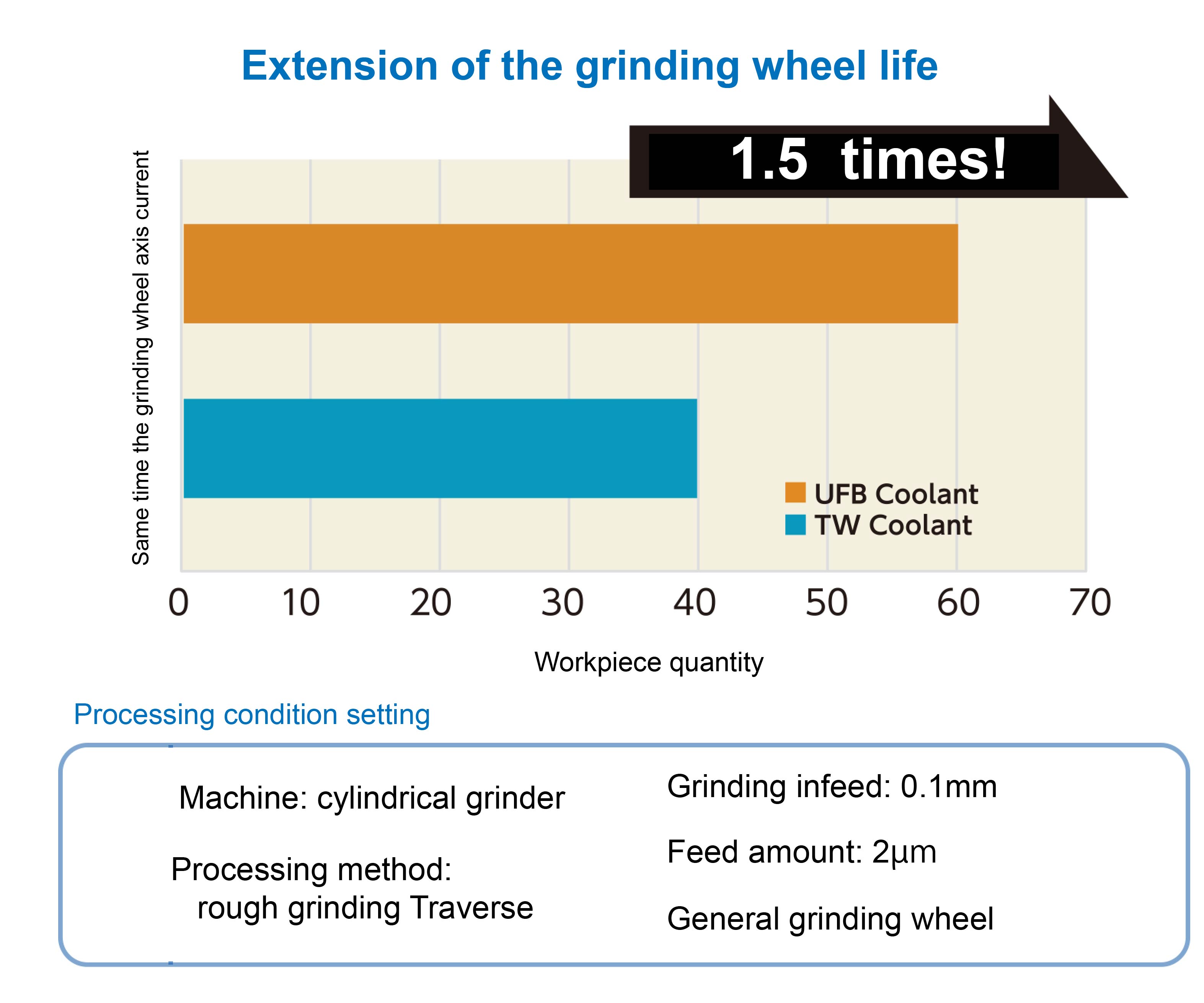

- Extends the life of the grinding wheel

- Increased depth of cut, higher cutting speed

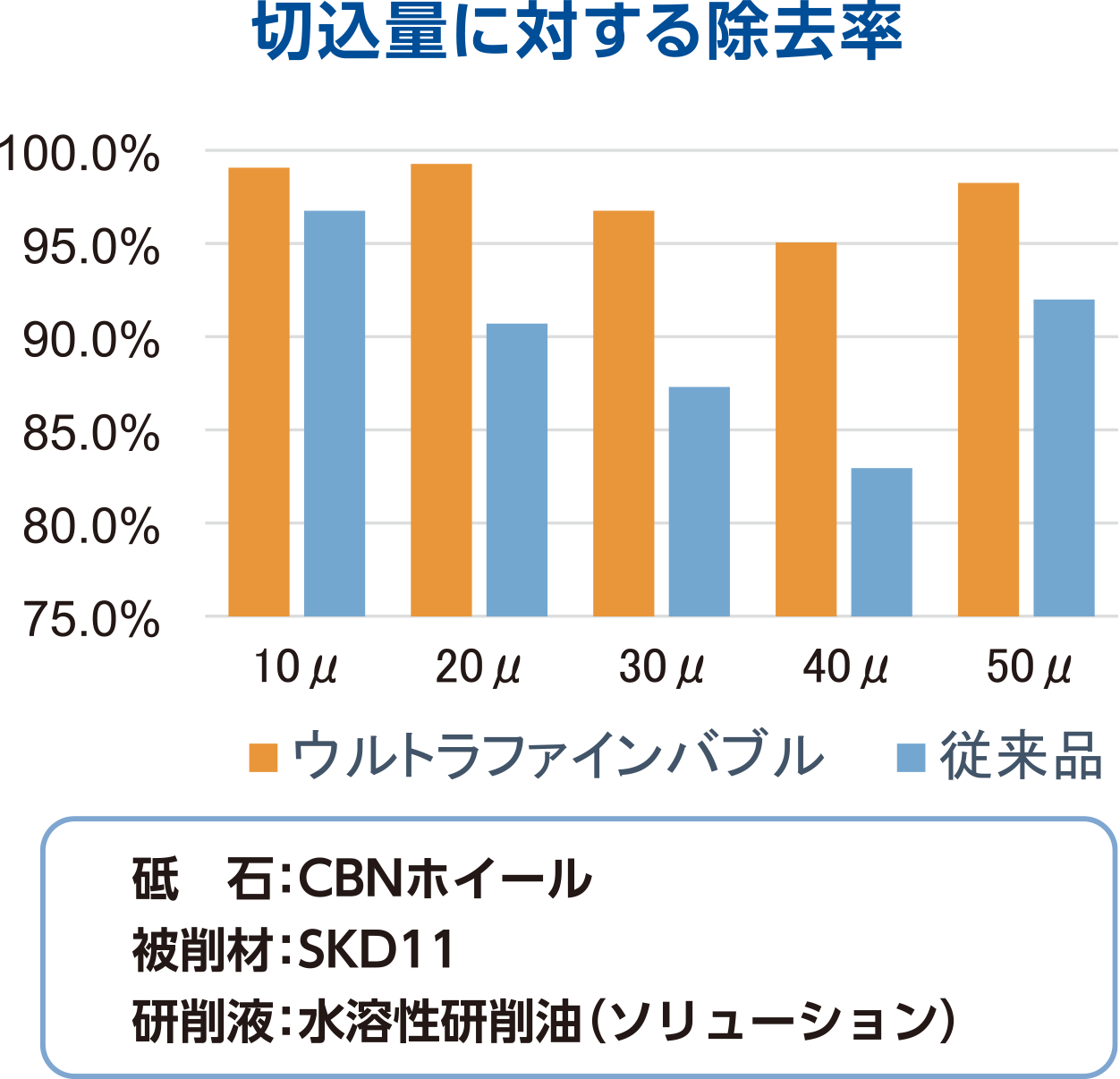

Improved processing efficiency

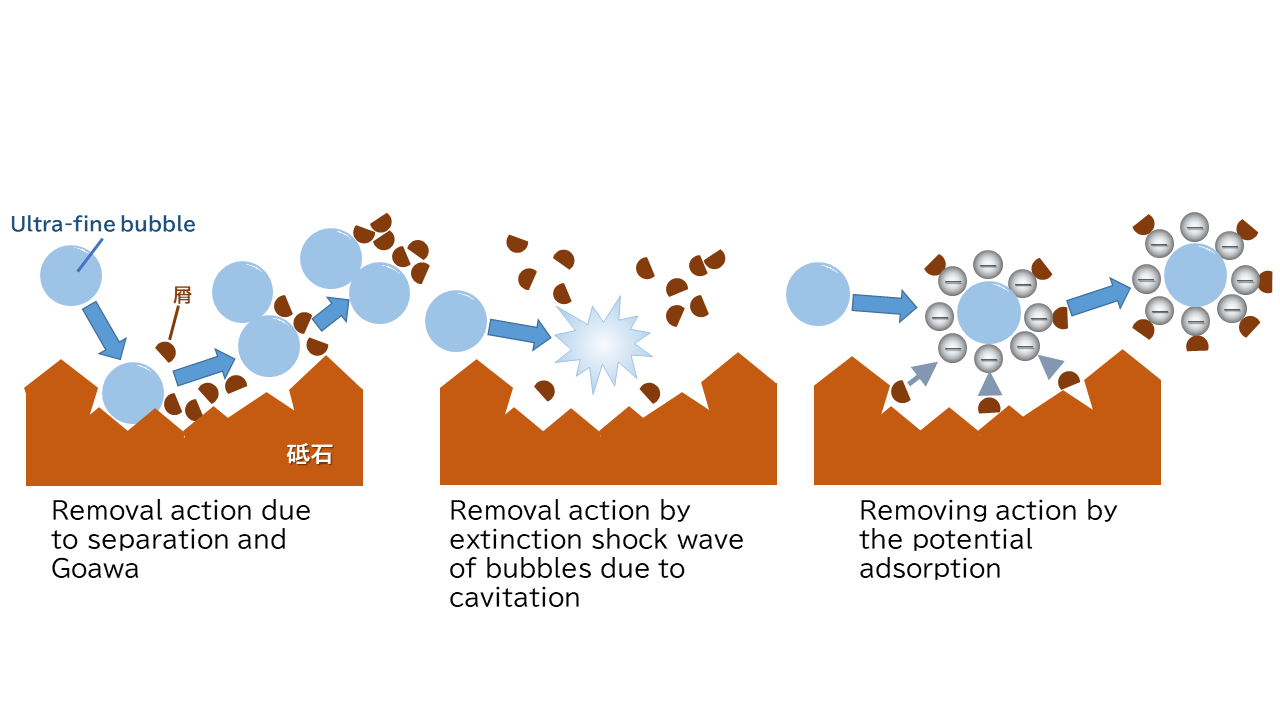

Bursted bubbles with high inner pressure (approx. 20 atm.) remove grinding chips of a grinding wheel by cavitation.

This physical action makes grinding wheels sustainably sharp. As a result, you can increase a grinding depth of a work piece.

Prevention of coolant corruption

Many aerobic bacteria are generated as a result of increase of the volume of oxygen in a coolant. It prevents an outbreak of injurious bacteria.

Improvement of dimensional accuracy

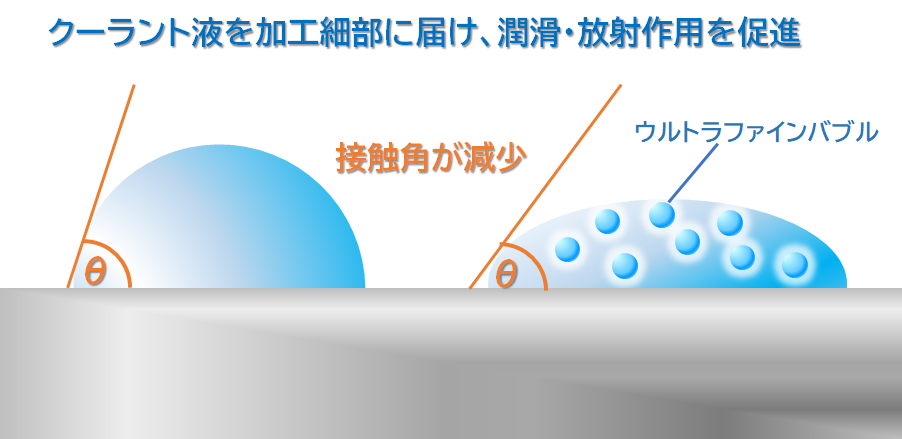

Due to the low grinding contact angle and the high wettability, you can easily reach a processing point on a work piece.

Moreover, you can also expect cooling effect by the heat of vaporization during the burst of Ultra-fine bubbles.

These effects lead to reduction of a heat stress and a distortion, and improve dimensional accuracy.

Life extension of grinding wheels

Sustainable sharpness of grinding wheels show dicrease of abrasive grain separation.

This results lesser dressing frequency and long grinding wheel life.

Support Tools

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.