Precision Surface Grinding Machine GS-64/65CV(s)

The environmentally friendly model of our best-selling machine has been newly launched

Significant updates from the previous model, including high-efficiency drive through electrification and improved rigidity achieved by optimizing the cast design.

A machine designed to meet the needs of modern manufacturing.

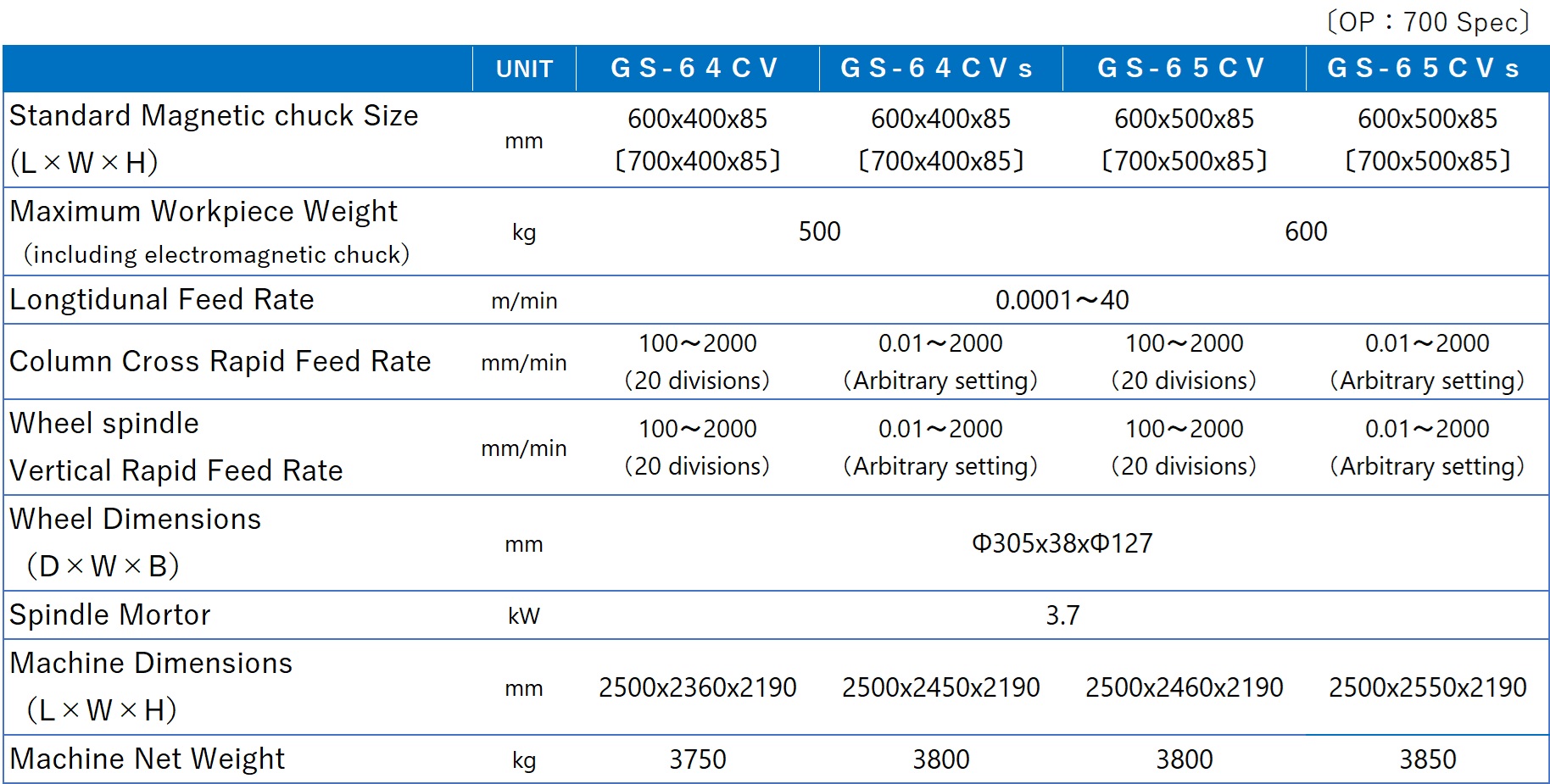

- Magnet chuck size 700x400mm and 700x500mm specifications are also available

MENU

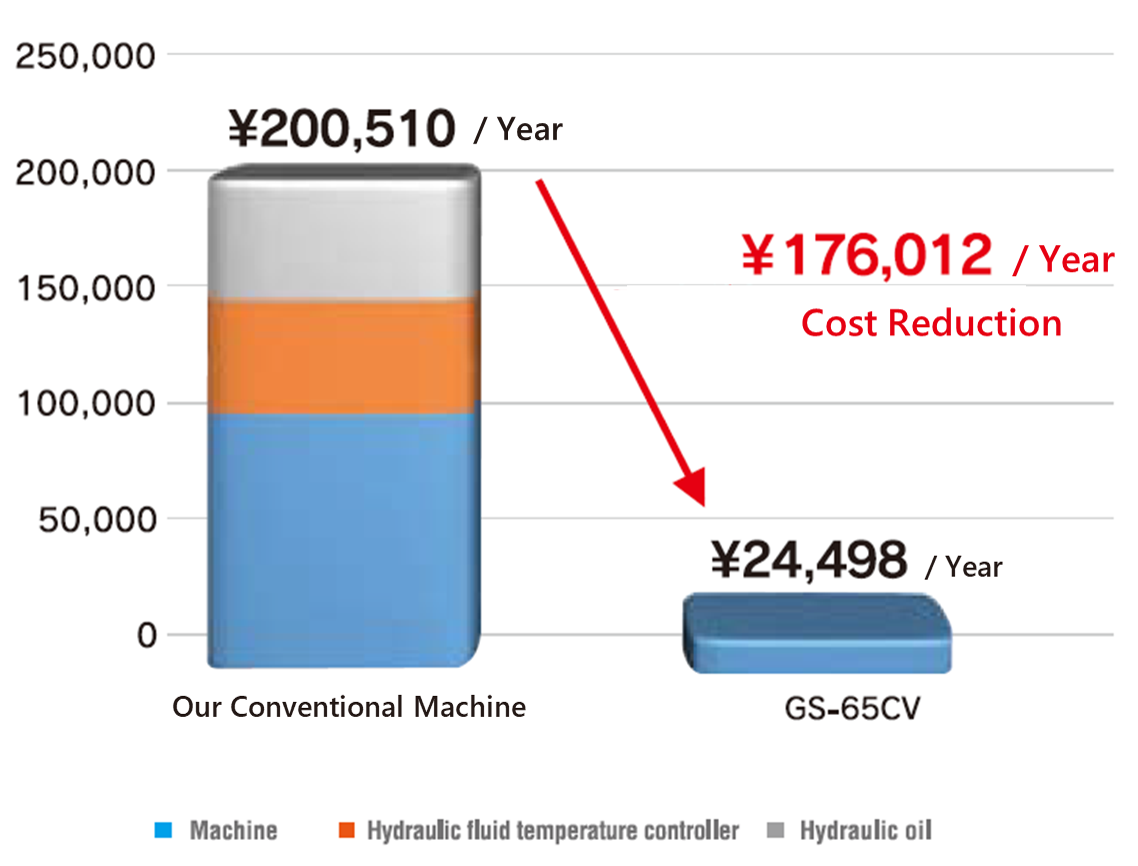

High energy-saving performance

Reduces power consumption during operation by 70%, significantly improving energy efficiency.

- A hydraulics-free machine equipped with AC servo motors for lateral feed and custom-designed in-house precision ball screws

- Reduced friction loss enables highly efficient operation

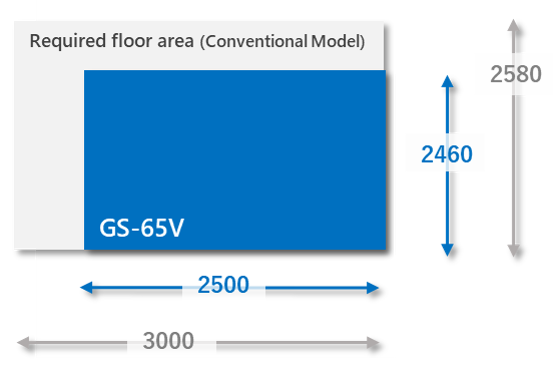

Reduced installation space by approximately 20% compared to conventional models.

- Compact design achieved by electrification and structural redesign, maintaining high levels of rigidity and machining accuracy

- Contributes to improved productivity on-site by effectively utilizing the saved installation space

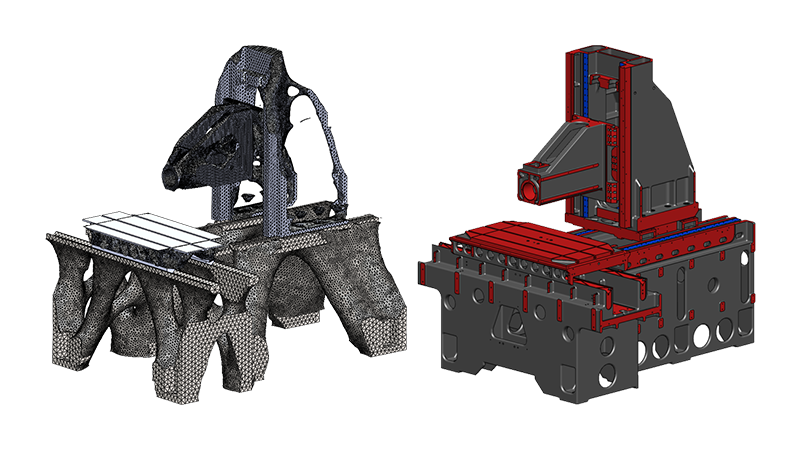

High-rigidity machine structure

- Optimized cast iron structure

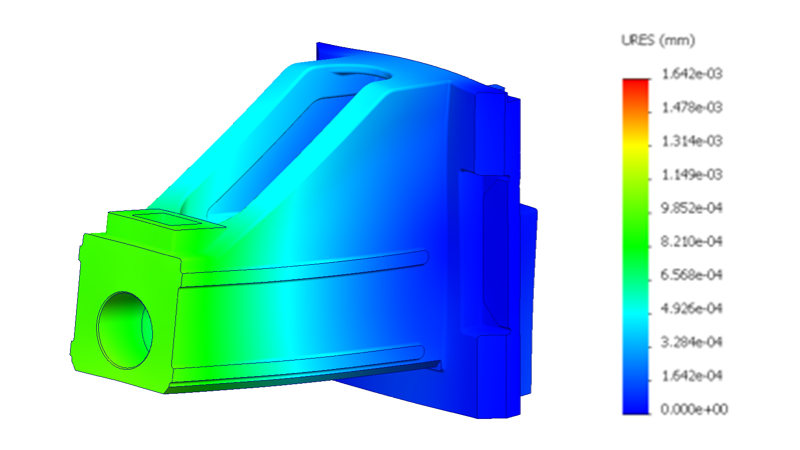

Comprehensive redesign of the casting based on topology analysis.

High rigidity and precision machining achieved by optimizing casting shape, thickness, and rib arrangement. - Spindle rigidity increased by 67%

Loop rigidity improved through topology-optimized design.

Minimizes deformation caused by grinding loads, further enhancing machining precision.

-

Topology analysis results

-

Measurement results of loop rigidity variations

Operator-friendly operability

- A handle and switch layout focused on operability, enabling easier workpiece loading and check the machining process.

Ergonomic positioning for grinding tasks, reducing operator fatigue.

Introduction to the Machining and Measurement Solution Room (Futtsu City, Chiba Prefecture)

- Our "Machining and Measurement Solution Room," located within our Futtsu factory, features operational machines on display.

- Test machining is available. Please share details such as workpiece size, shape, and target precision.

- Consultation booths in the room are available to discuss your problems, issues, and questions until you are satisfied with the results.

Support Tools

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.