What is axial clearance?

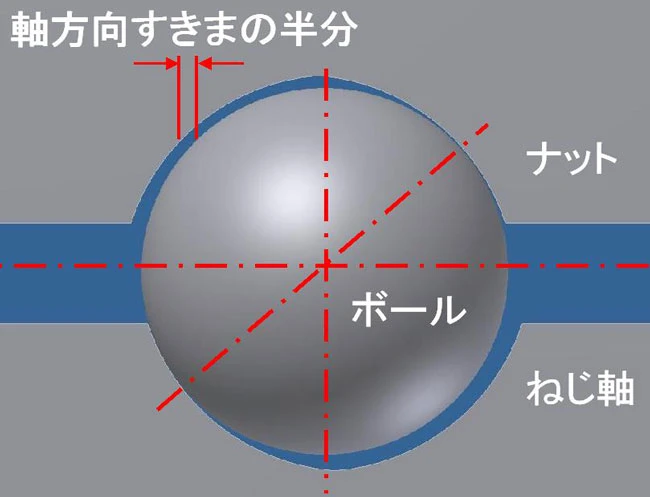

The screw shaft and nut come into contact with the balls at a contact angle represented by the diagonal dotted line as shown in the diagram below.

The amount of axial movement is the distance until the contact angle reverses, so 1/2 of the axial clearance is the dimension shown in the diagram.

Conventional sliding screws (triangular threads, trapezoidal threads, etc.) have the disadvantage that when the axial clearance is reduced or made zero, the force (driving torque) to rotate the screw shaft becomes very large, requiring a large amount of power.

In addition, because it is a sliding contact, it wears out a lot during use, making it difficult to maintain the specified axial clearance. The feature of Ball Screws is that even if the clearance is made zero, the increase in driving torque is very small compared to sliding screws due to the "rolling contact" with balls between the screw shaft and the nut, so it is a suitable machine element for feed screws (*2) in devices (such as machine tools) where backlash (*1) is an issue.

For feed screws in devices where axial clearance is not an issue (such as transport devices that only move luggage), there are cases where the advantage of having an appropriate clearance is to suppress the driving torque and heat generation due to operation.

The axial clearance of Ball Screws is 0.005mm or less, 0.010mm or less, 0.030mm or less, 0.20mm or less, etc., and it is necessary to select the appropriate clearance depending on the application.

- Backlash is the "gap" that is necessary for mechanical elements that mesh with each other and move, such as slide screws and gears.

- Due to its application, a "feed screw" that converts motor rotation into linear motion desirably has zero axial clearance, and there is a demand for no (or little) backlash.

Technical information list about Ball Screws

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.