Press Tool & Die Systems

With our unique technology and network,

we provide our customers with the most suitable, highly efficient motor cores.

In the global context, it is said that a staggering half of all electricity consumption is attributed

to motors. Furthermore, within Japan, over 75% of the power consumed in the industrial sector is by

motors. This immense demand for motors speaks to how indispensable they are to both our daily lives

and industrial activities.

Against this backdrop, our company contributes to energy conservation and efficiency in society

through our precise mold technology and motor core products. In particular, our main products, Press

Tool & Die and motor cores for automotive applications, continue to enjoy robust demand.

To meet the increasing expectations of our customers, our company is actively expanding its supply

capacity. Specifically, in addition to new capital investments such as the expansion of our Nagano

Plant, we are strengthening our production and supply system for Press Tool & Die Systems and

motor core products by expanding business with overseas partners and broadening our domestic

partnership strategies.

Moving forward, we will continue to contribute to the realization of a sustainable society and the

advancement of our customers' "monozukuri" (craftsmanship/manufacturing) through our

precise technology and strategic business development.

Press Tool & Die Systems Related Videos

-

Product Introduction Video

Precision press products Glue FASTEC®

Ideal for ultra-thin laminates! Realizes highly efficient, high quality, and high precision motor cores.

See details of precision press products Glue FASTEC®

-

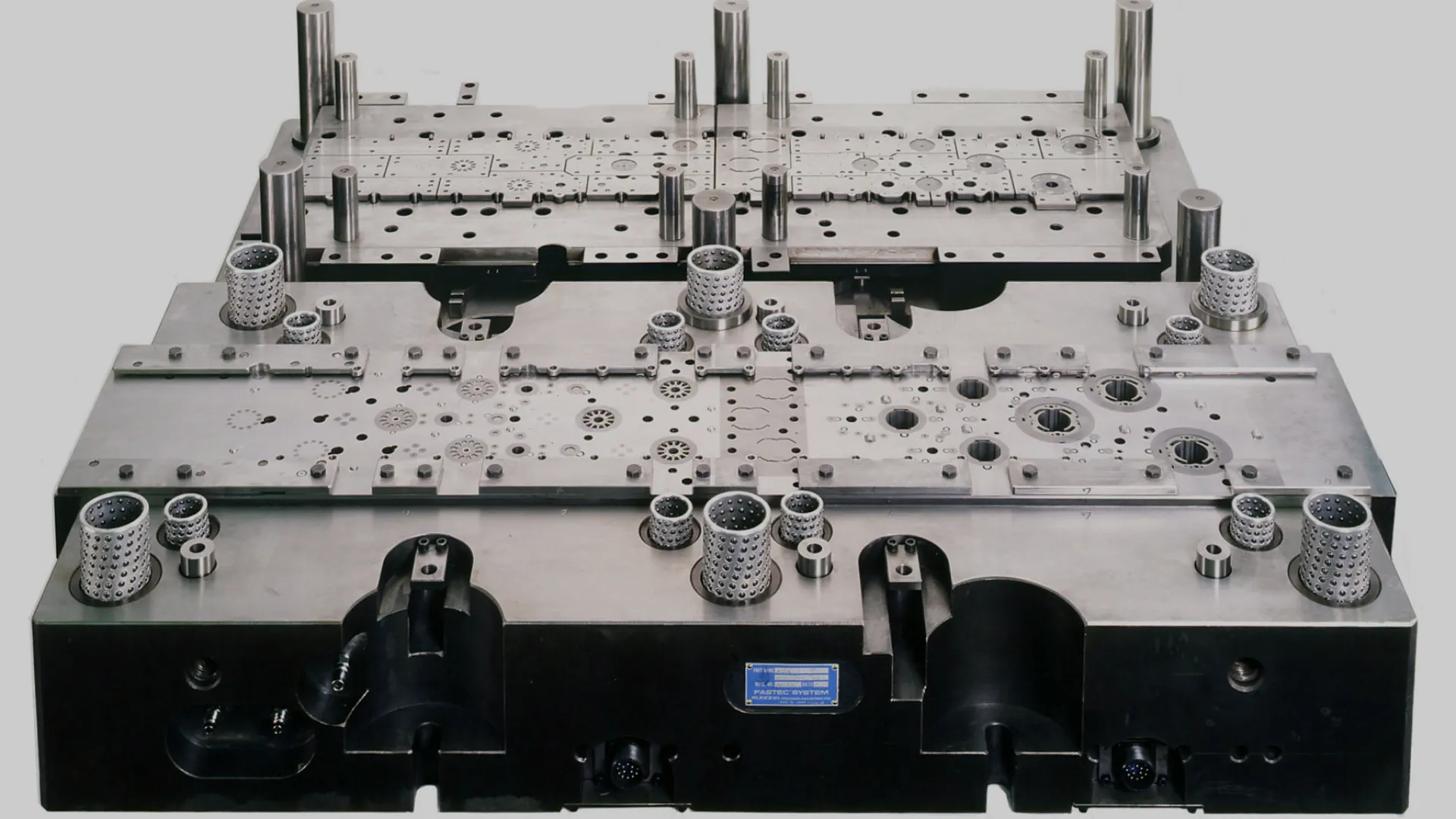

The FASTEC® system is a revolutionary system that uses adhesive to bond thin sheets together, enabling automatic stacking inside a mold while maintaining insulation.

We sell press products produced using dies tailored to customer specifications.

-

Awards

- Nikkan Kogyo Shimbun "Super Monozukuri Awards" Automotive Parts Award

- Excellence Award at the "Monodzukuri Nippon Grand Awards" sponsored by the Ministry of Economy, Trade and Industry

- 38th "Materials Industry Technology Award, Minister of Economy, Trade and Industry Award"

Precision press products LASER FASTEC™

Specialized for extremely small workpieces. Achieves secure holding power even with extremely small shapes.

See details of precision press products LASER FASTEC™

-

LASER FASTEC™ is a technology developed for mass production of high-precision small thin laminate products.

By using a YAG laser to fix together the laminated sheets, it is less subject to restrictions on product shape and can mass-produce small thin laminate products with stable strength and quality, which was previously difficult to achieve.We sell press products produced using dies tailored to customer specifications.

-

Precision Press Products FASTEC®

Low cost and extensive know-how. We can handle a variety of shapes.

See details of precision press products FASTEC®

-

This method involves forming dents and dowels in thin steel sheets, then pressing them together to fix (caulk) the upper and lower thin sheets together while laminating them. This method has also been widely adopted for HEV main motor cores.

We manufacture custom-made tool & die bodies.

-

Permendur motor core

High-speed external bonding lamination technology has made long-awaited mass production a reality.

Precision press tool & die for motor cores

Punching, lamination, measurement, and assembly are all carried out inside the

mold.

We support the creation of optimal motors using three different methods.

See details of precision press tool & die for motor cores

See the catalog of precision press tool & die for motor cores

KURODA's laminated press tool & die "FASTEC® System" was launched in 1976 as a press tool & die for motor cores, based on our polishing technology for spline gauges and precision jigs. This system made it possible to complete all the work processes of punching, laminating, measuring, and assembly within the press process, resulting in a dramatic improvement in quality and productivity. In an era when high-efficiency motors with excellent energy-saving characteristics are in demand, we can manufacture optimal motor cores tailored to customer needs with high precision and efficiency.

FASTEC® is a registered trademark of KURODA, derived from

"FA-stening" (fixing)

"S-kewing" (skewing technology)

"TEC-hnology"

We only accept custom-made dies for "Precision Press Products FASTEC®".

Motor core post-processing (MAGPREX®)

This is the process of inserting magnets into the motor core and fixing them in place with resin.

Inquiries About Products

Please contact us using the inquiry form or your nearest sales office.